Alright, so for the next module I decided to go with YASH, as I already said before. At first I was thinking about making a jfet sample&hold. Just because It seemed easier and… I don’t know, maybe I just love transistors. But after receiving J111 and experimenting with it a bit I realized that what I got is, probably, a fake jfet. It didn’t work like jfet at all. I was trying to make a simple circuit to check if this J111 is fake or if I am stupid and this one is real… BUT while thinking about it I just decided to go with Yash, which is also a very simple circuit. No way to mess it up, right? Hahaha. There are many ways to mess it up if you are me.

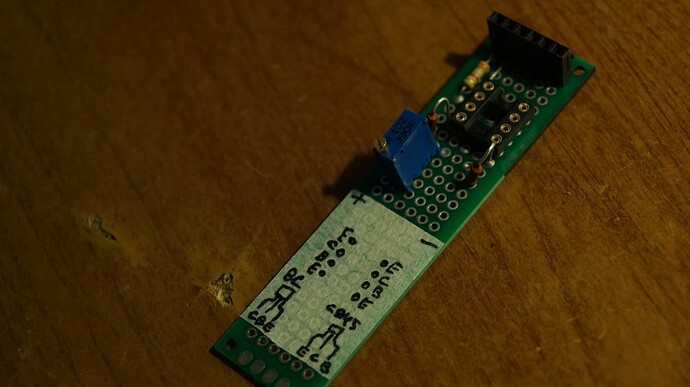

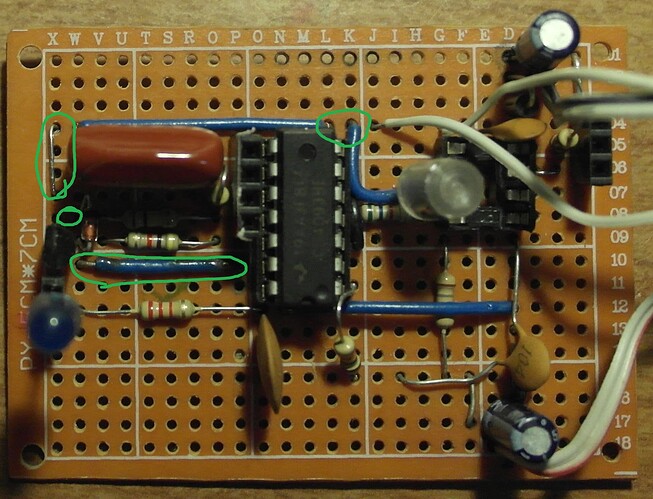

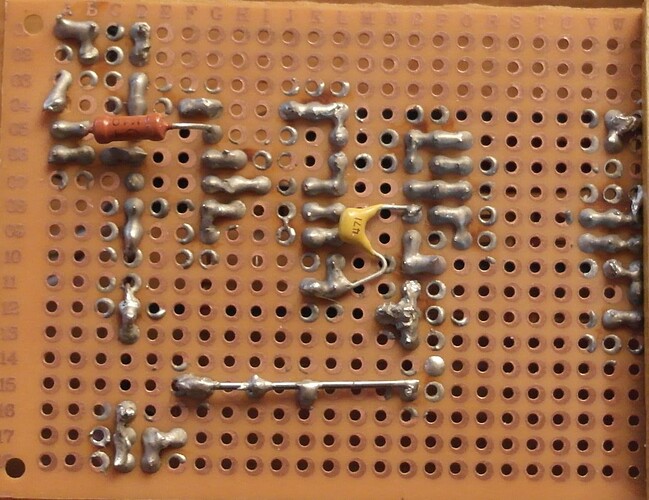

So look at the board. See the green marks? That’s all the places I forgot to add or solder together.

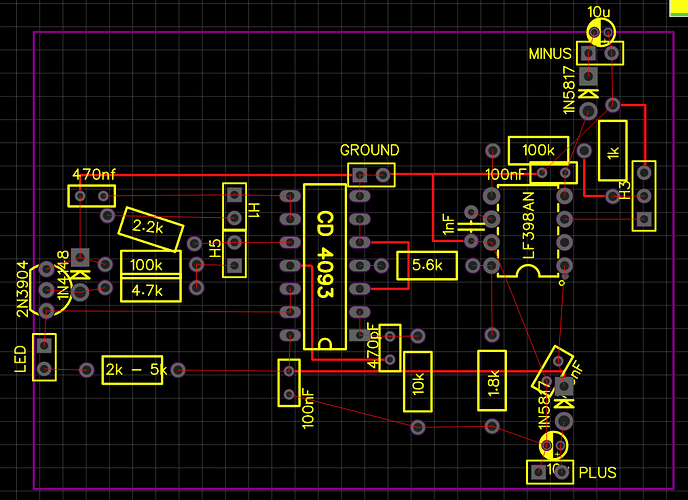

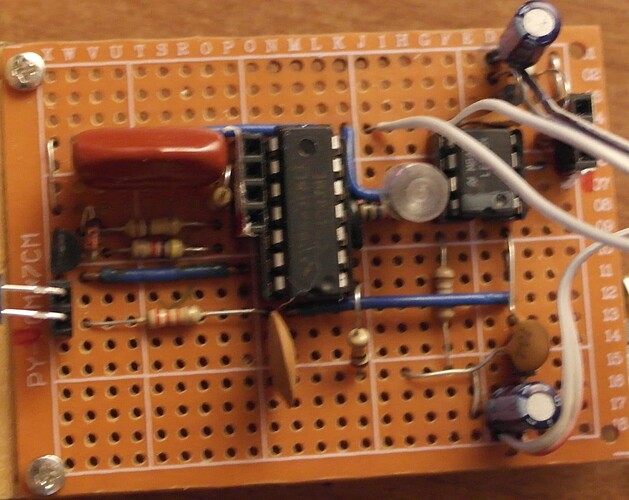

And it still doesn’t work for some reason. I don’t know what might be the problem here. I am 80% sure it should work now. But it doesn’t! While checking the circuit it appears that the pulse from the inner oscillator almost disappears before reaching the LF398 (which goes to the slot at the right side of the board). And if that’s not enough to make me depressed, something wrong with jack inputs/outputs too. My fault totally, I bought a big pack of cheap jack sockets. Well, I am sure this problem is solvable, even if I would have to destroy the socket, remodel it and put it back together again. The circuit, however, needs more attention, and I am not sure what’s wrong with it. Could be that I have a faulty CD4093, but that’s the only one I have, so I can’t just replace it to see what would happen… I also caught a very annoying cold and it makes it extra difficult to concentrate and check the circuit while looking at the schematic (which is mirrored and a bit different, because I was doing it at easyeda and it’s a pain to search for the footprints)

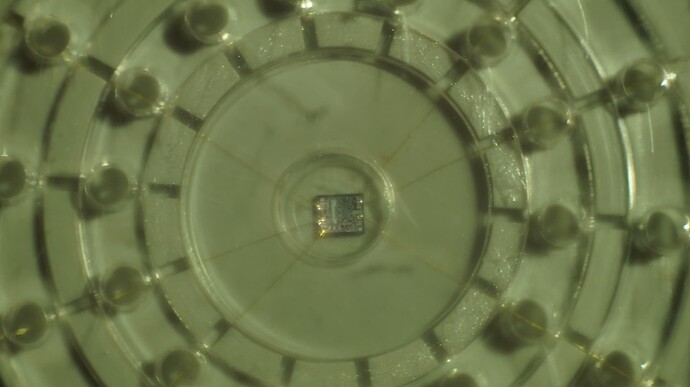

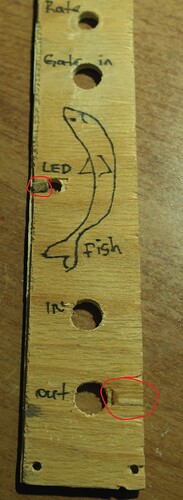

But as I started this thread with front panels, I must show you the front panel for this module. It is ready! Shame that module itself isn’t working… Alright, here’s my process. I already shared the photos, but let’s do it again!

At first I cut a plywood. I don’t really care if it’s not perfectly rectangular, but I am trying to make it as good as it could be. I cut it with a knife, because it’s thin. And also it’s easier for me to use a knife than a saw.

Then I cut 1-2 cm from the upper/bottom side and place it with my other modules to see if it’s fine. If it is, I mark the screw positions (forgot to mark it here) and jack sockets positions and other stuff that I think I would need.

Then I usually measure it again, just to be sure that I wouldn’t encounter any problems with placing the panel elements and mark the markings, because unmarked markings are as confusing as this sentence.

I drill holes and file the plywood, at the spots where I will place the jack sockets. I wish I had a filing machine or something. Hate it.

Then I glue the stuff that I damaged while drilling the holes. And after that I glue the aluminium “face” to the plywood.

The finish line! I poke holes with a screwdriver and clean it with a knife, then paint it, et voila!

Then I add a pretty picture from the internet and write with a gel pen words like “IN” and “OUT” and all these user friendly interface elements. And at the back I write the name of the schematic and a name of an artist that made the illustration that I used

1-2 layers of lac and we’re ready!

Sadly I can’t show you how it looks when it works, because it doesn’t work. But I will try to fix it and then I will show you how cool it looks when blue LED light blinks! Super nice.

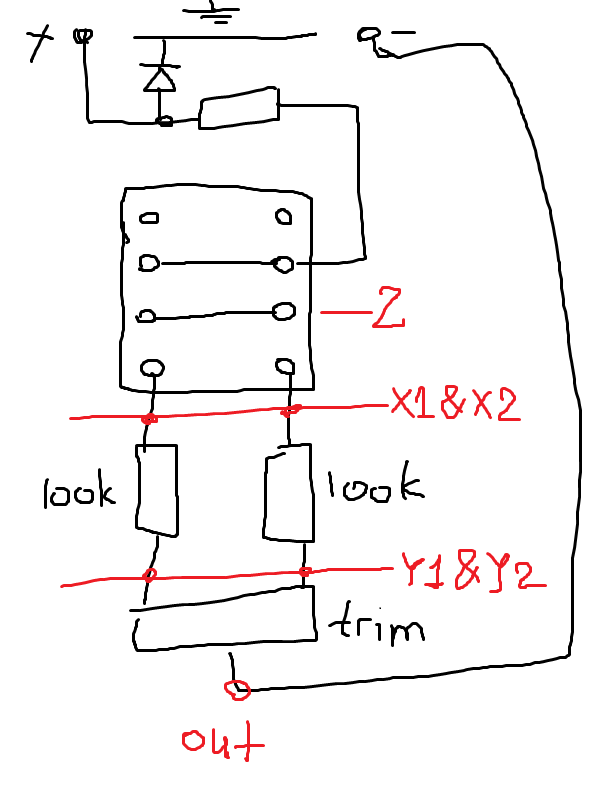

Anyway if you have any ideas what could be wrong with my schematic, I would appreciate it. I know that there’s not enough information, so here’s my eda project:

And both sides of a board:

I am not desperate yet, so it’s not like I am begging you to sit for an hour searching for what I did wrong, haha. But if there’s something obvious that you noticed right away, please let me know!