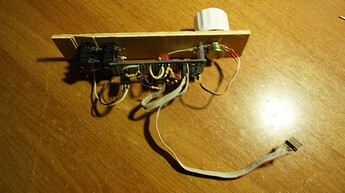

Alriiiight. So here’s the result. It is a bit ugly, but it has a story

And here’s this story!

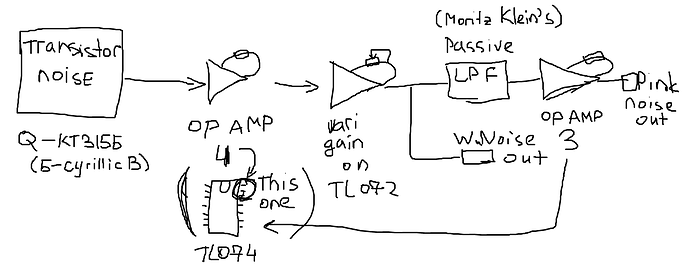

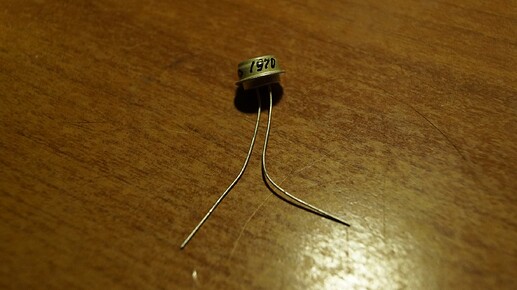

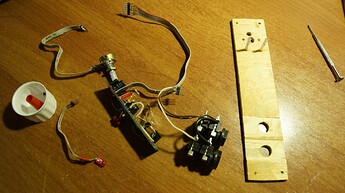

I will start with the electronics side of things. For some reason I just couldn’t make the pink noise work. Something is broken or maybe I was sloppy when soldering, but here’s what was happening: as long as there was only the white noise circuit on the board, everything was perfect. Then I added the pink noise part and everything got weird. White noise wasn’t loud enough, pink noise was just clipping all over the place, so it wasn’t even pink. Alright, I though, that’s probably because I accudently made a tin bridge somewhere. So after two days of trying to fix it, I decided to just redo everything from scratch. White noise - perfect, pink noise… not okay. Again. So I decided to re-read all the schematics and info… Nothing, everything is correct, but it doesn’t work. And that’s why there’s no pink noise here, haha.

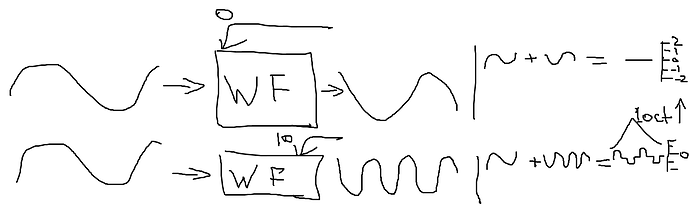

Just for the people who would like to diagnose the problem (not that it matters now) - here’s a simplified schematic:

Sorry if it is confusing, but I binned the original detailed schematic after a nervous breakdown (that’s not true, I just binned it because there was no need to keep it).

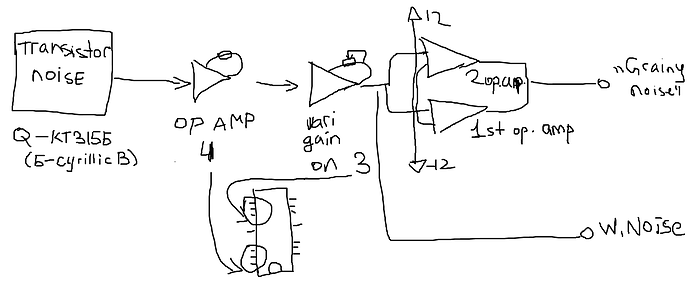

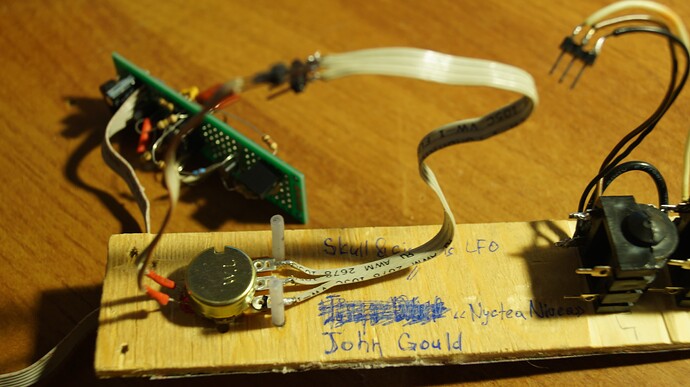

Alright now we have this situation (and everything works):

As you can see, there’s no TL072, so could it be that it was faulty? I am not sure. I don’t know. We’ll see when I try to use this chip later for something else

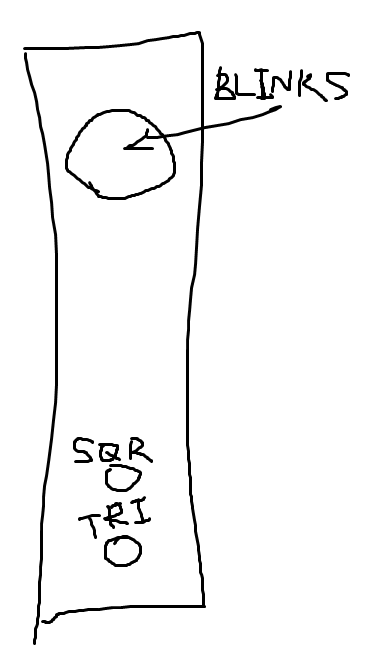

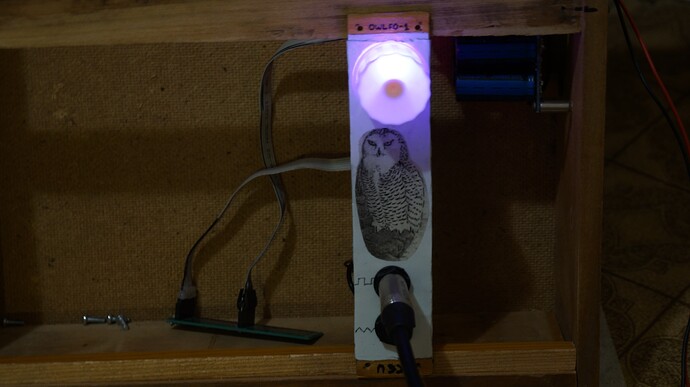

And now the front panel saga!

As you see, there’s a piece of plywood. Yeah, I decided to go with this plan. So I took plywood and just glued a layer of aluminium from an old beer can on top of it. There’s a reason why I did that. I just don’t like how painted wood looks. So I needed something smooth and unicoloured. And aluminium cans is a great resource, it’s very easy to find, easy to paint and easy to throw away if something isn’t right with the size or quality or… something. Also it looks like you need just one layer of paint to make it look great. Bad sides are: it’s not this easy to glue it onto plywood, it’s thin, it has pretty sharp edges, it splinters if you are not careful when cutting it out from a can. Also it takes paint well, but keeps it not this well. What I mean is that you can scratch the paint layer easily. Too easily. So that’s why I repainted it second time.

After painting it I was a bit unhappy about how boring it looked and painted some straight lines with the black acrylic paint. It didn’t go well… So I had to hide my painting mistakes, and my best though was to use a picture that I downloaded from the internet. But it would be kinda lame to just glue it on the panel, so I decided to somehow transport this picture from paper straight to the acrylic surface. I was stupid, yes. Turns out even slightly hot iron melts the paint (it was only one day after painting) and… this is very dumb, but after seeing how hot iron is not good, I started to think about acetone. And you know what… Who knew that this extremely aggressive solvent would also melt the paint… After all these experiments I had to re-paint the panel twice, first time I sprayed the paint a bit too narrow. Narrowly? I don’t know, english is hard. Anyway, that was the last time I used pant on this panel, but 4 layers of paint is a bit too much for this kind of surface

And well, I just couldn’t continue with this thing anymore, so I cut another picture that I downloaded from shutterstock (and you can see that on the photo) and just slapped it right on still wet acrylic. For some reason it didn’t take, after an hout it was still unglued, so I put it in the vise and pressed it onto surface. Now it sits perfect, but everything around it got smooshed and it looks ugly. Alright, I though, next time I should use a lot of rubber. And as I had to glue the scale for the potentiometer, it was a perfect opportunity to check if it works. Well, it kinda works. But at the same time it’s not better than just pressing paper into paint with a wooden stick or something. Also I forgot to check the pieces of rubber that I used and there was something bad on it, some kind of grease… And that’s why it looks like shit! It wasn’t my fault (it was).

Anyway, that was an experimental module. So I am quite happy with the information I got. I am not happy with the result, but it’s better than nothing, I guess. And also who cares! From afar it looks great!

*ah! I forgot to mention that it is based on two very slightly modified schematics:

Maritz Klein’s coloured noise (It was a starting point)

MFOS Noise Cornucopia (that’s why my module is called Maize, Corn - Maize, I know Cornucopia isn’t about corn. Also noise - maize and bloody maze it turned out to be at some point. And also I was able to get the popcorn sound on the breadboard. I can’t make it with the finished module for some reason. Probably because LEDs are different. Anyway, It’s quite fitting)