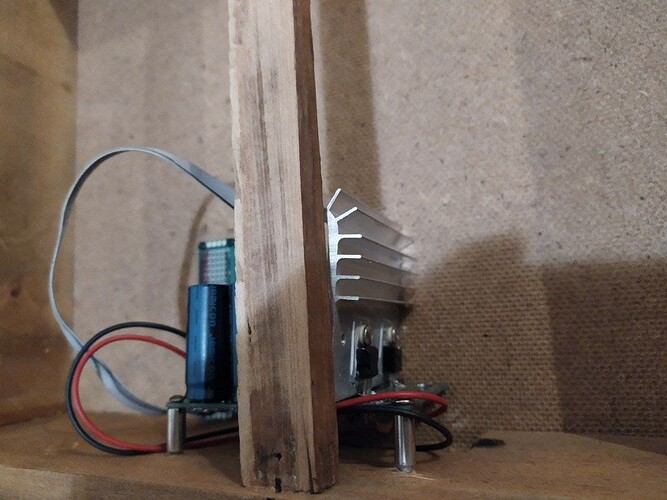

A little update. It took me a week to make a case. I hate woodwork… Just to compare: PSU took me two nights and it works fine, although I think it’s a little usafe. I will redo it if there would be problems. PSU is based and, well, copied basically from Mateusz Kranz (I mean, Moritz Klein) schematic. I know there are better solutions, but I just decided to go with this one.

I made it for kinda custom sized panels, so there’s no need to be precise with 3U, 4U or whatever. It is close to 4U though. I think 4U is about 177mm and the space between panels in my case is 34cm which is, when divided, gives me 170mm. So close enough.

I don’t know if hanging PSU like that is a good idea, but we’ll find out! I did it to maximise the useful space in my case. As it hides behind the middle shelf\rail\whatever, it gives me a lot of free volume to work with. I decided to face the heatsink up, cause everybody knows that heat goes upwards and i am concerned about all of my capacitors, I don’t want to cook them like you do with a grill chicken or something.

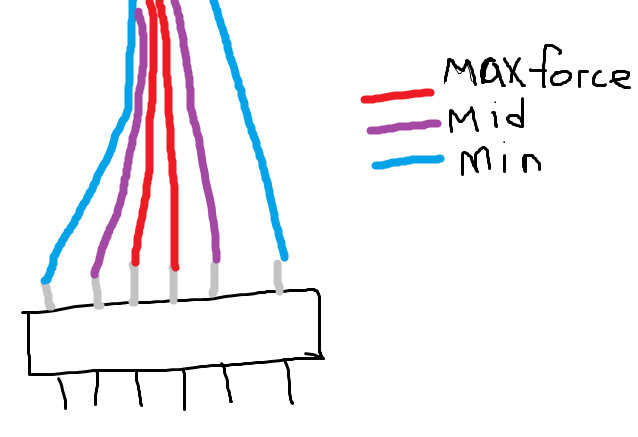

Next step would be the power distribution line.I think I will do it on demand though, so one pinheader should be fine for now as I have three modules planned, one of which has been on my breadboard for a week or so, so it’s almost ready (it is ready as is, but…)… It is a noise module that I will show in the next update, I think. It is also based on Mateusz’s video, but I want to make some changes before transporting it to PCB. Like adding LEDs for the outputs and transporting it to TL072 as I don’t really need a blue noise output.

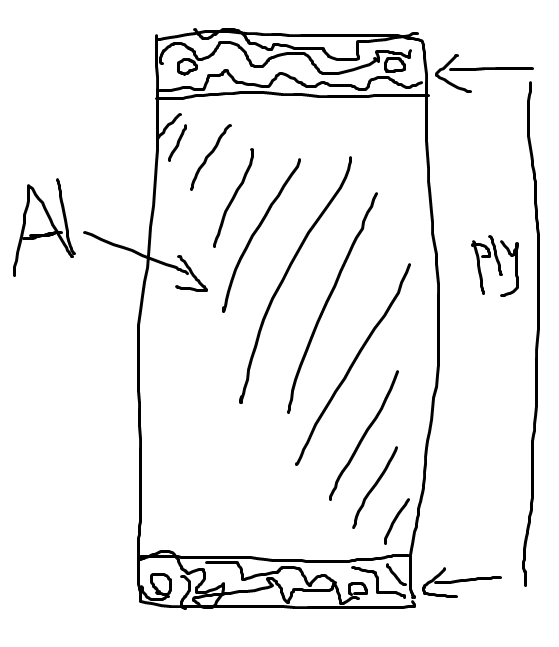

For the front panels I decided to use plywood with some aluminium foil or a beer can wrapped around the middle of it (and probably painted white, maybe black, or maybe I would just leave the metallic shine). It should look like this:

Good thing I have a piece of plywood that is a bit larger than 17cm in height and maybe 60cm long. A lot of material to experiment with. I imagine the plain plywood would look like ass in this kind of casing, which is also wood. I am not very fond of all wood electronic stuff. Not because of the fire hazard, it just looks wrong to me. I could paint it, but the texture would be weird and… the whole thing is splinter-inducing, I don’t want to add some extra splinter-friendly stuff. So I want to try aluminium while maintaining the wooden look, hopefully it would be not extremely bad.

And that’s all for now! I will show you some new updates in the future, maybe when the first module with a panel would be done. Then maybe I will show you a couple of other modules and leave this thread for internet archeologists in the 25th century