First up, two new modules, as promised!

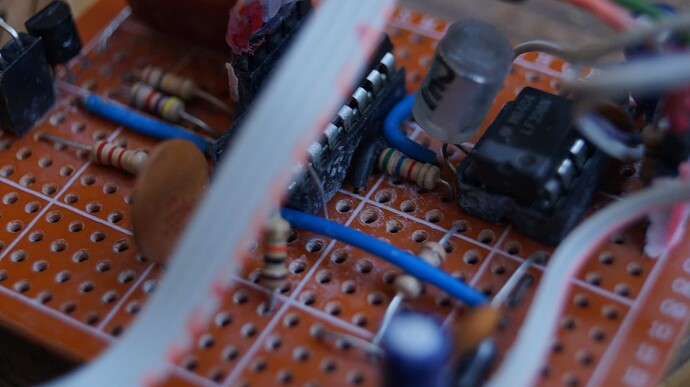

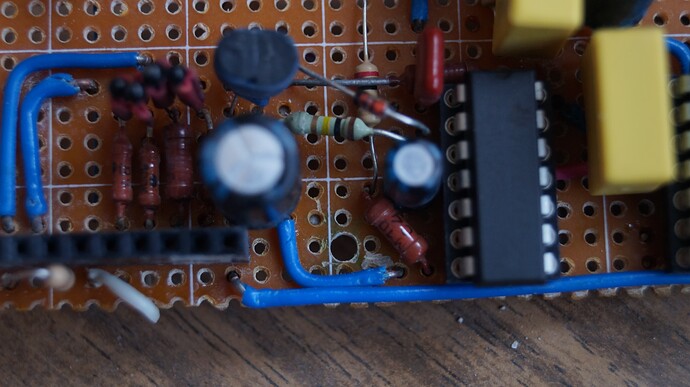

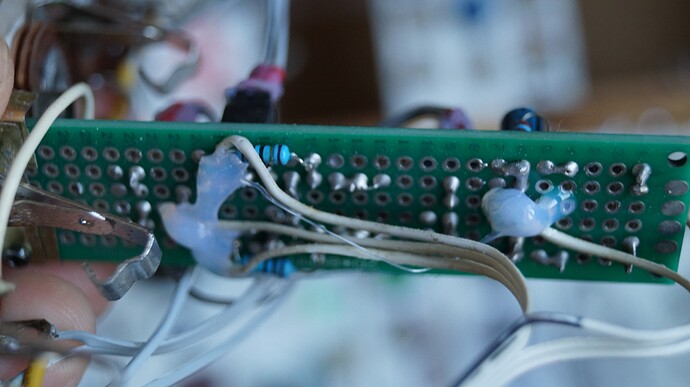

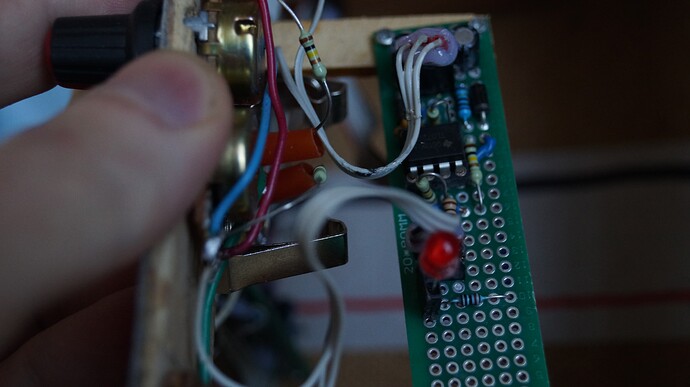

This one is a mixer. Based on NLC 4hp mix. It’s right in the middle, between LFO and VCO. It is a DC mixer, but I am using it for audio, because I am this kind of person. As I said a week or so ago it’s called “Gu”, not only because I am pretentious, but also because I wanted to have some kind of linguistic diversity in my rig. I know a little bit of chinese, not enough to read and speak freely, but I like it! It’s a very cool language. It sounds cool and written language looks cool… All these characters. It’s sexy! That’s how I see it. Ethiopian, arabic and mongolian also look cool, but these ones I don’t know at all. The only thing I know is that “Cat” in mongolian is “Muur” or something like that. Very cool!

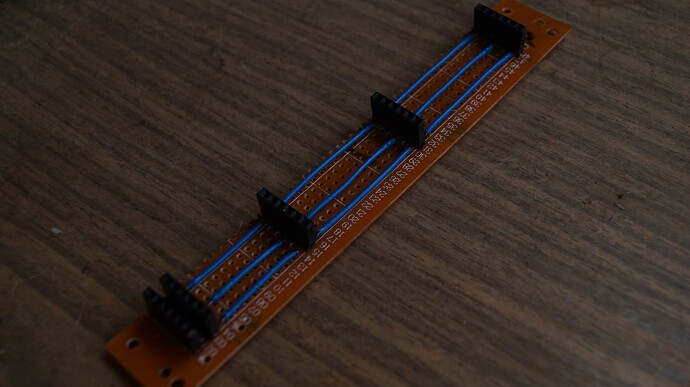

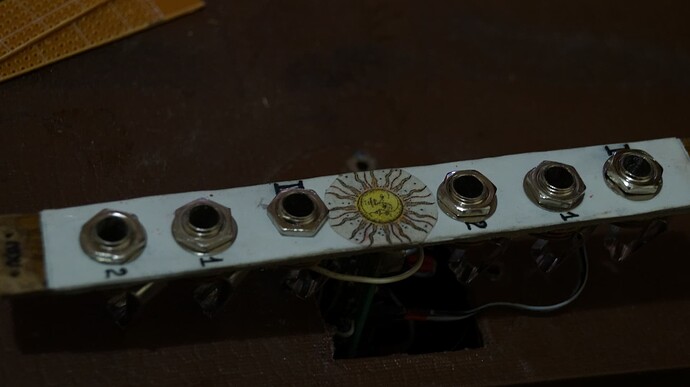

The other module is 2x2 mult.

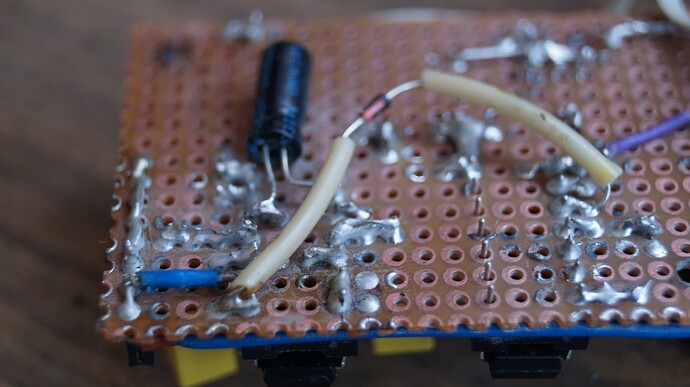

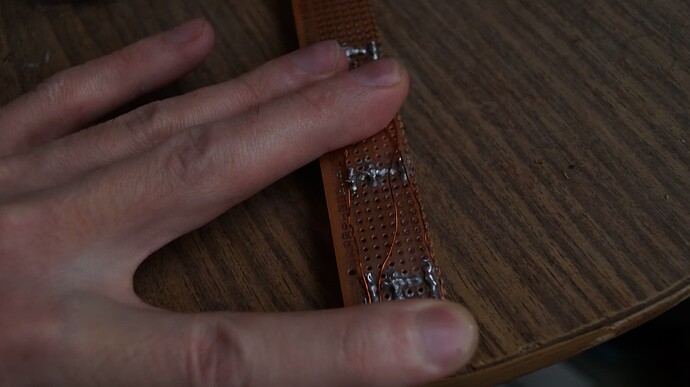

Based on whatever I used for my previous mult. It works, but it’s not in the rig. You see on the previous photo that everything is just… hanging there on pure gravity and friction. When I finish powerlines for the second level of this case, I will screw everything on, but for now it’s just like this. Alright, mult. It is actually 1x4 mult if you don’t connect anything into the second input, so the lower half is normalized to the upper one. I feel like I should’ve done it with my first mult too… This way I have more possibilities and it’s overall more flexible. But oh well.

One more thing before we go to my AliEx adventures…

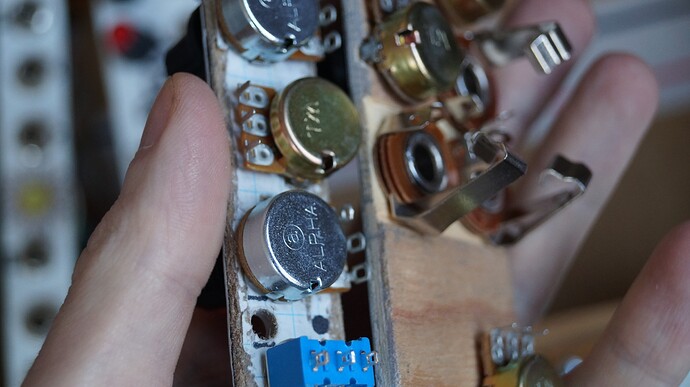

DIY handles! Or knobs if you never giggle hearing this word. It’s bad. Not really centered, not really round… But that’ll do for now. I need some kind of machine that makes things round. It’s expensive though and I can’t see how I would use it when not making knobs. It would be useless… So I need another way of doing this.

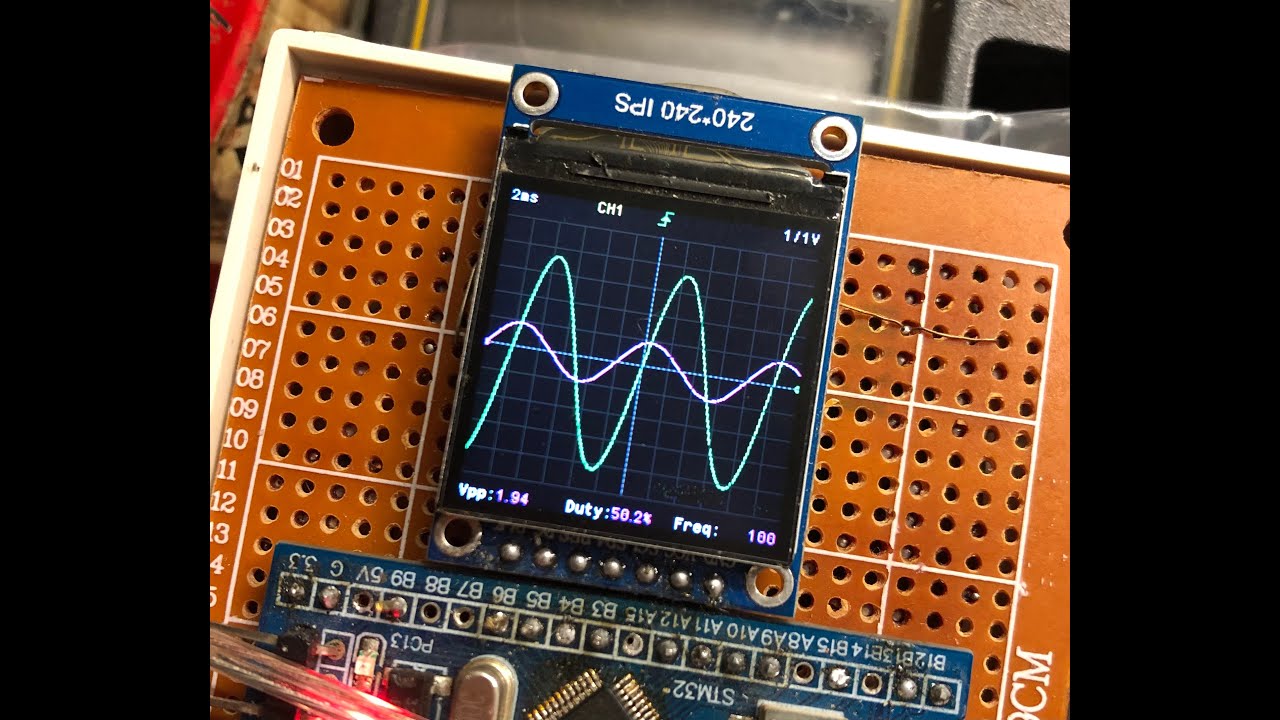

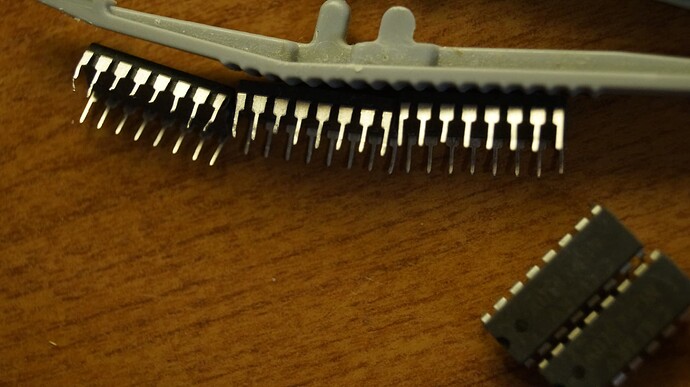

Okaaay, now for the AliExpress mishaps! First I’ll list everything I got, as it might help me to remember what I wanted to do with these things… So I got 20 pcs of 6,5mm jacks, finally an STM32 (yes, the blue pill that was mentioned three days ago) and ICs:

CD40193 (I bought like a lot of them for some reason, I think I was trying to buy something else, but misclicked and only noticed just now, so now I have like 20 of them)

CD4015

CD4016

CD4050

CD4051 (I accidently bought 20 instead of 10)

CD4052

CD4081 -everything seems fine with all of the CD ICs-

DG411 - it seems fine too, DMM shows that switches are in the 0v position (1 and 4 on, 2 and 3 off - at least that’s what I’d like to believe), which is expected.

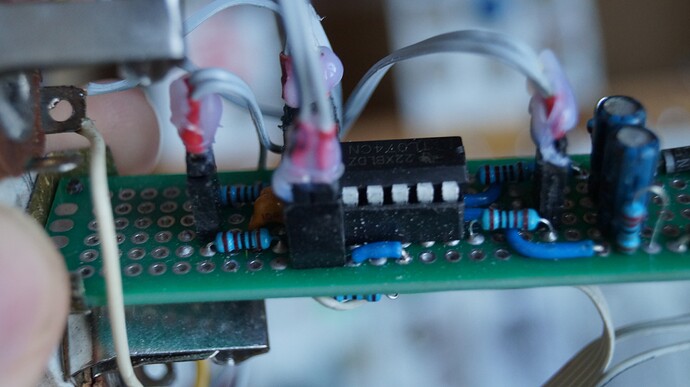

DAC0800. Now this one was a very weird order. I actually received 9 DAC0800s and one ADC0834. All of the DACs were different. Look!

Very weird! Anyway, ADC is good though. And I don’t need 10 DAC0800s. I Think I needed one or two for the turing machine… But not 10. So that’s alright.

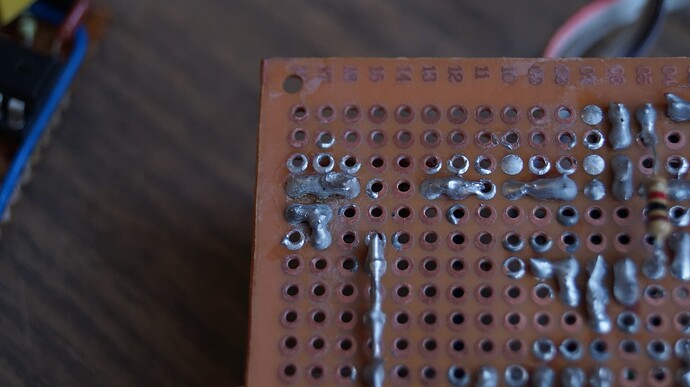

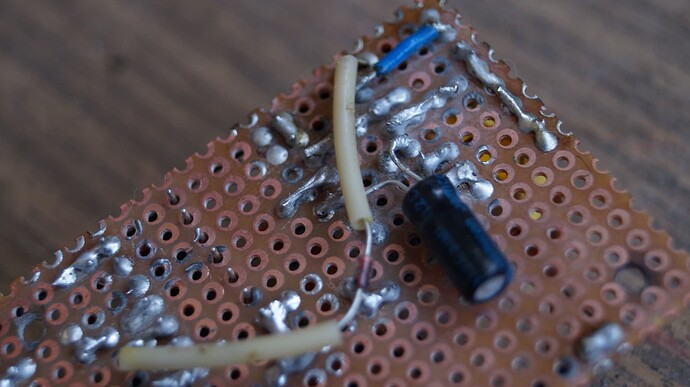

But then we have AD7524s. I’ll show it first

So all 5 of them were desoldered, you can see solder on the pins. And 3 of them had their pins broken or cut off. You can see it on the photo. Given all that I had little hope that they would work at all, so I wrote a complaint at AliEx and I also made a claim to refund. The dispute, they call it. And very quickly I received a result, a judgement of the great Ali court, haha. They’ll refund 100% without me having to send these ICs back. And I didn’t wanted to send it back, cause if one of them works - I’ll use it anyway, even though it would be with some inconvenience. And if they all don’t work and I send it - they will sell it again! So yeah, now I have (presumably broken) ICs and money. That’s my AliEx story for today. The moral is - don’t buy stuff from the small stores.

Although… One thing that I noticed while looking for the envelope these ICs were sent in, is that the person that sent me bad DAC0800 is the same person that sent me bad AD7524! Even though the stores were different. They also had very similar tracking numbers (before they were merged into one megapackage, the Voltron package). So… my journalistic brain expands it to maybe a dozen of different stores, that are actually one store. Again, a Voltron store that is trying to maybe trick the chinese tax system. Or Hong Kong tax system, I am not sure how autonomous HK is now. So I see a conspiracy that should be inspected… I have like more than a hundred of different orders from Ali (both the ones received and on the way here) and I never looked into who sent it. Could it be that there are actually 10-20 big stores with branches that are registered on different people to avoid taxes or anti monopoly laws… But that’s what I will check from now on. Names and emails and phone numbers of senders! Very interesting.

Anyway! I have a little video for you. It’s very dark, but it sets the mood!